About Us

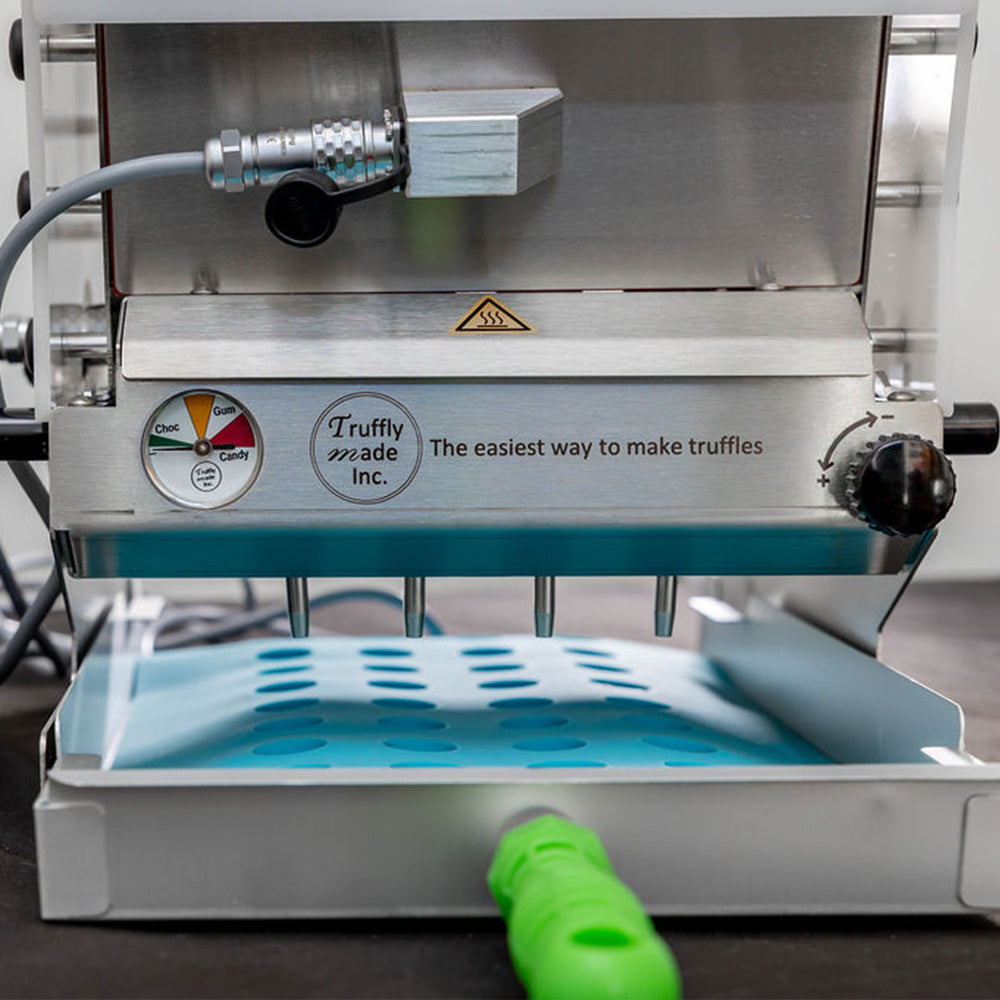

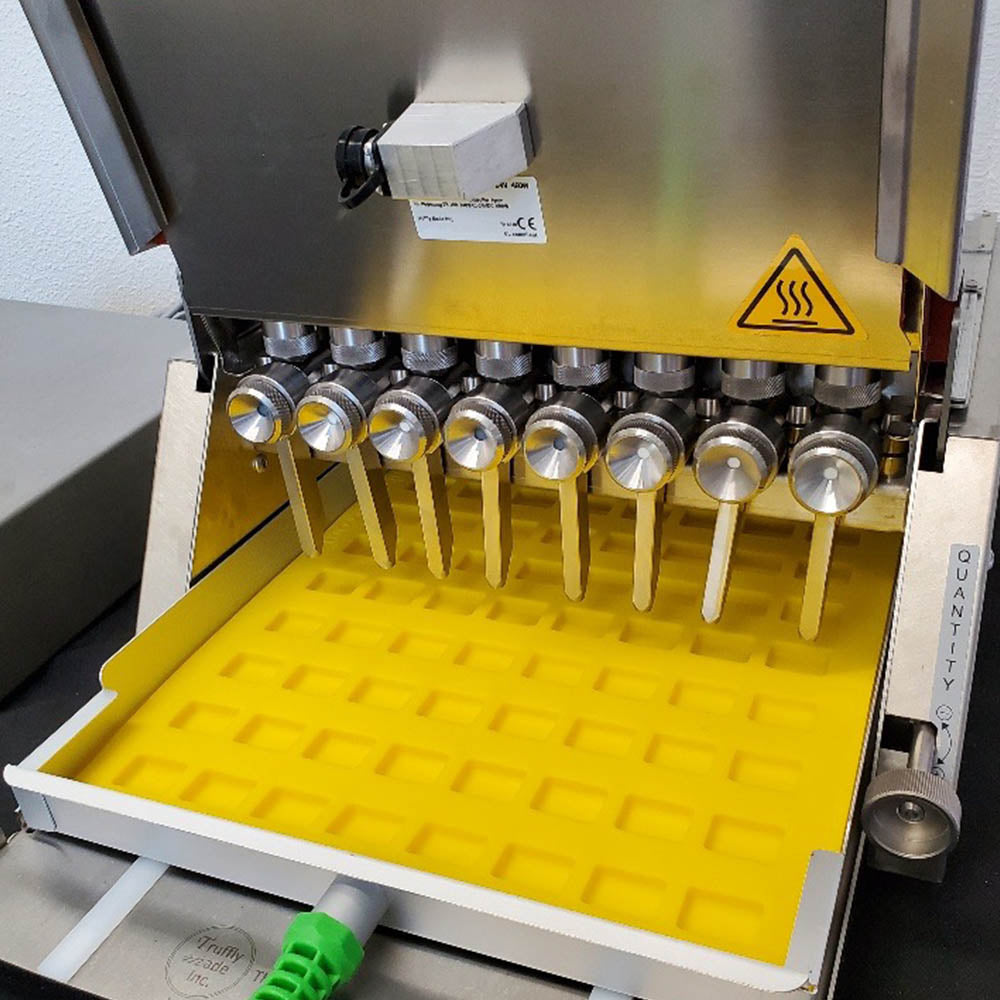

Since 2013, Truffly Made has been producing top-quality German-engineered candy depositors, demolders and silicone molds. Our FDA-approved and BPA Free silicone molds are designed for professional confectioners, featuring a patented design that eliminates the need for handcrafting or purchasing shells, streamlining the candy-making process.

Truffly Made molds are unique, allowing candies to be easily removed in a single step. These non-stick, food-grade silicone molds are user-friendly, easy to clean, and reduce labor costs. Built for commercial use, they withstand temperatures from -40°F to 450°F, enabling seamless transitions from oven to freezer.

Our Universal Depositors and Demolders crafted from the highest-quality, food-grade 304L stainless steel, boost productivity, precision, and output, eliminating the need for manual mold filling and increasing production by thousands of units per hour.

Truffly Made also provides recipe development and optimization services. Our experienced food scientist can create tailored formulas or refine existing recipes to meet your specific needs.

Our equipment is perfect for creating a wide range of confections, including chocolate, ganache, caramel, gummies, pralines, hard candy and more!