Technical Support

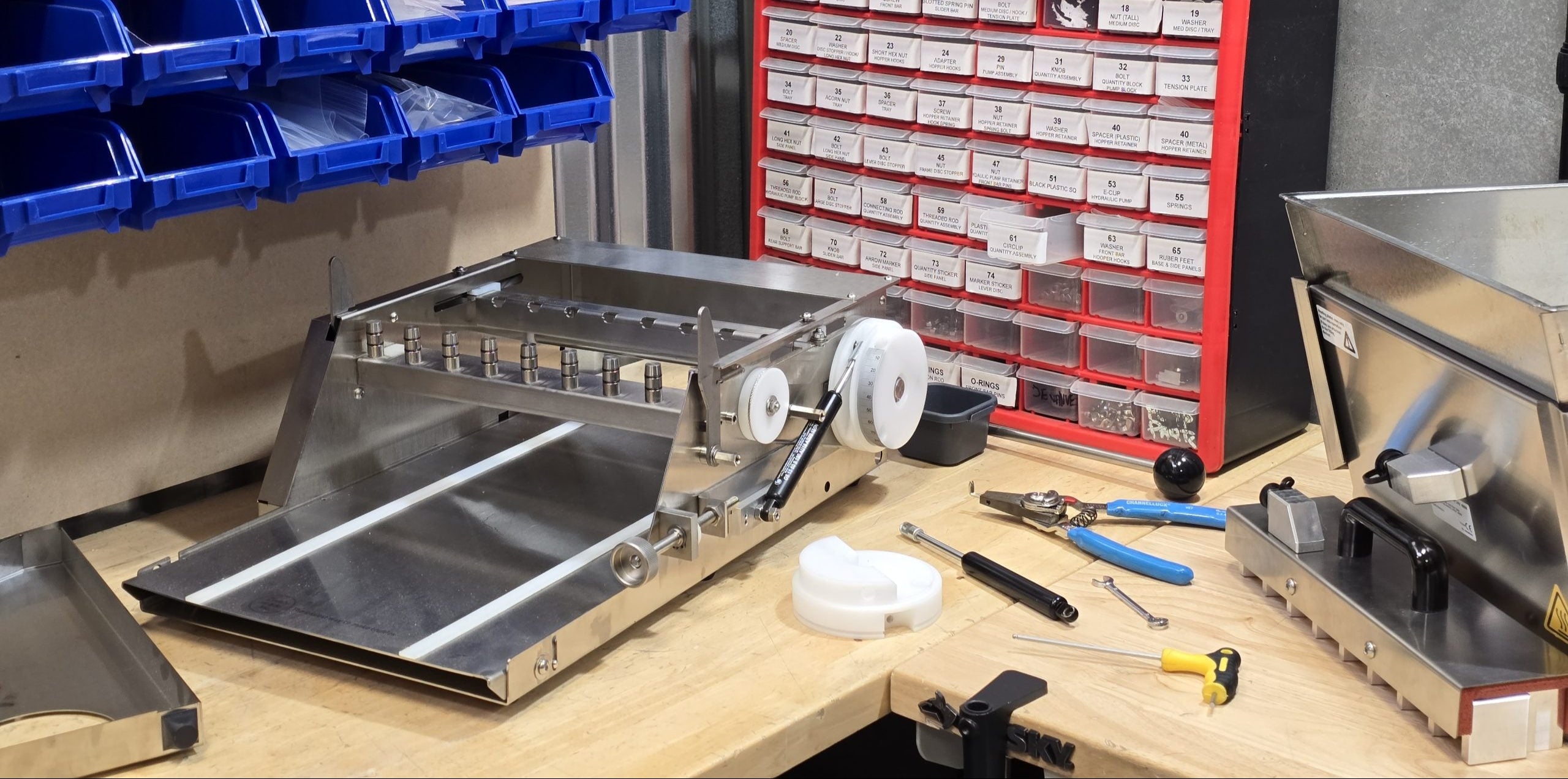

Maintenance encompasses all the work required to keep machines running successfully. This includes everything from regularly scheduled service, routine checks, and both scheduled and emergency repairs. It also includes replacement or realignment of parts that are worn, damaged, or misaligned. Service Maintenance can be done either in advance of failure or after failure occurs. In addition to providing maintenance services at its facility, Truffly Made offers on-site technician support for swift and efficient service.

For more information, contact info@trufflymade.com

Frequently asked questions

What if I need help maintaining or repairing my equipment?

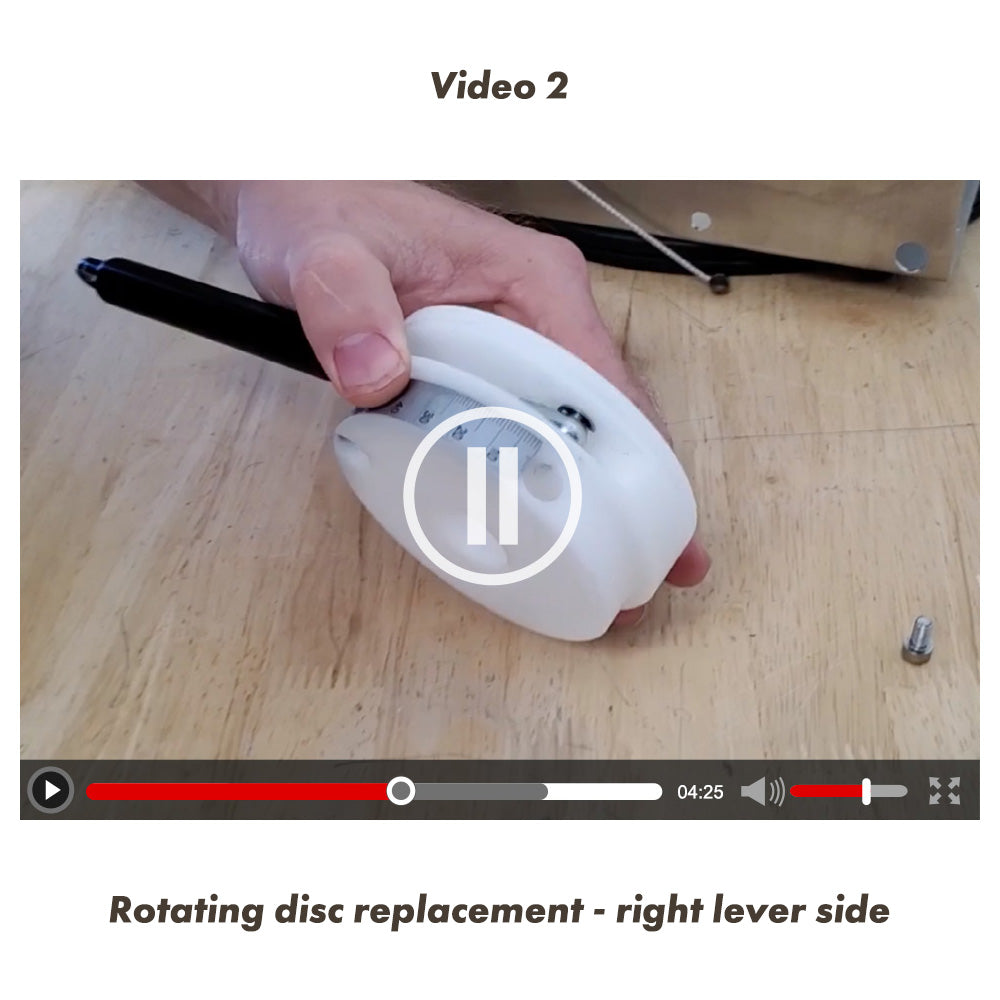

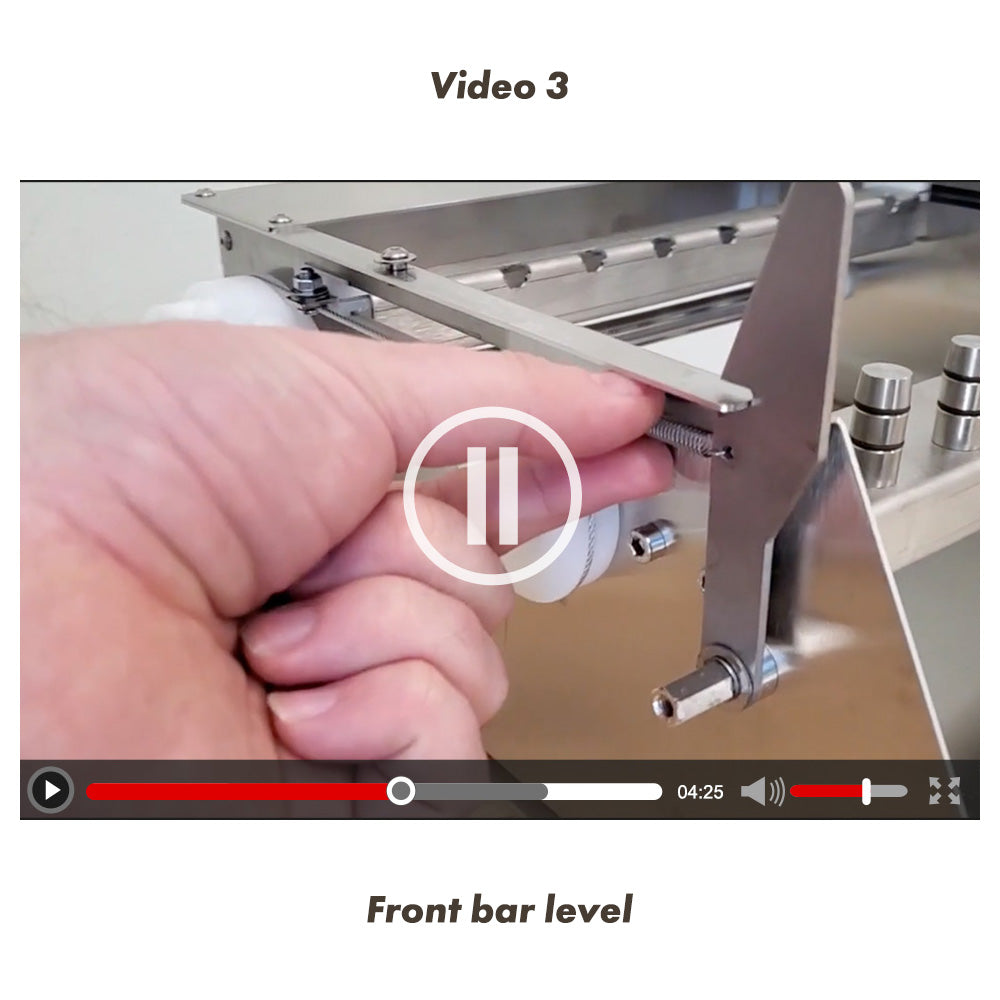

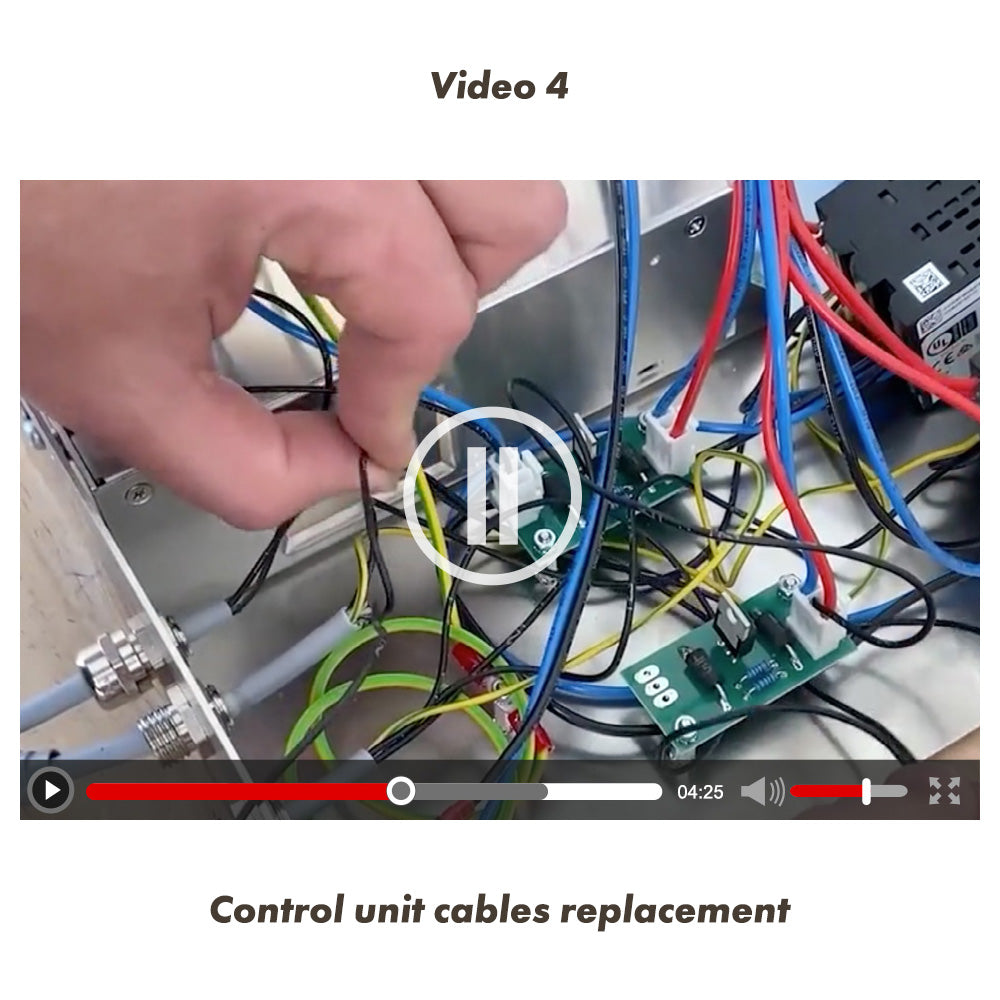

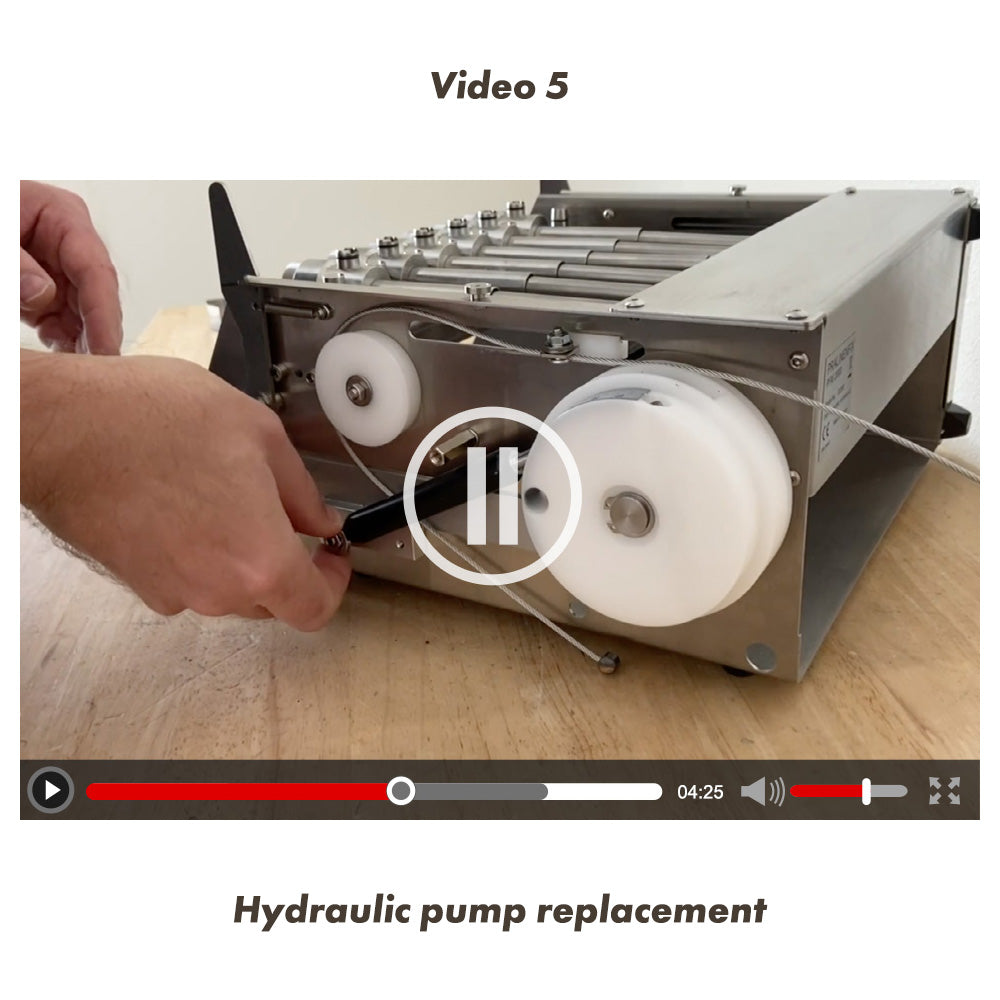

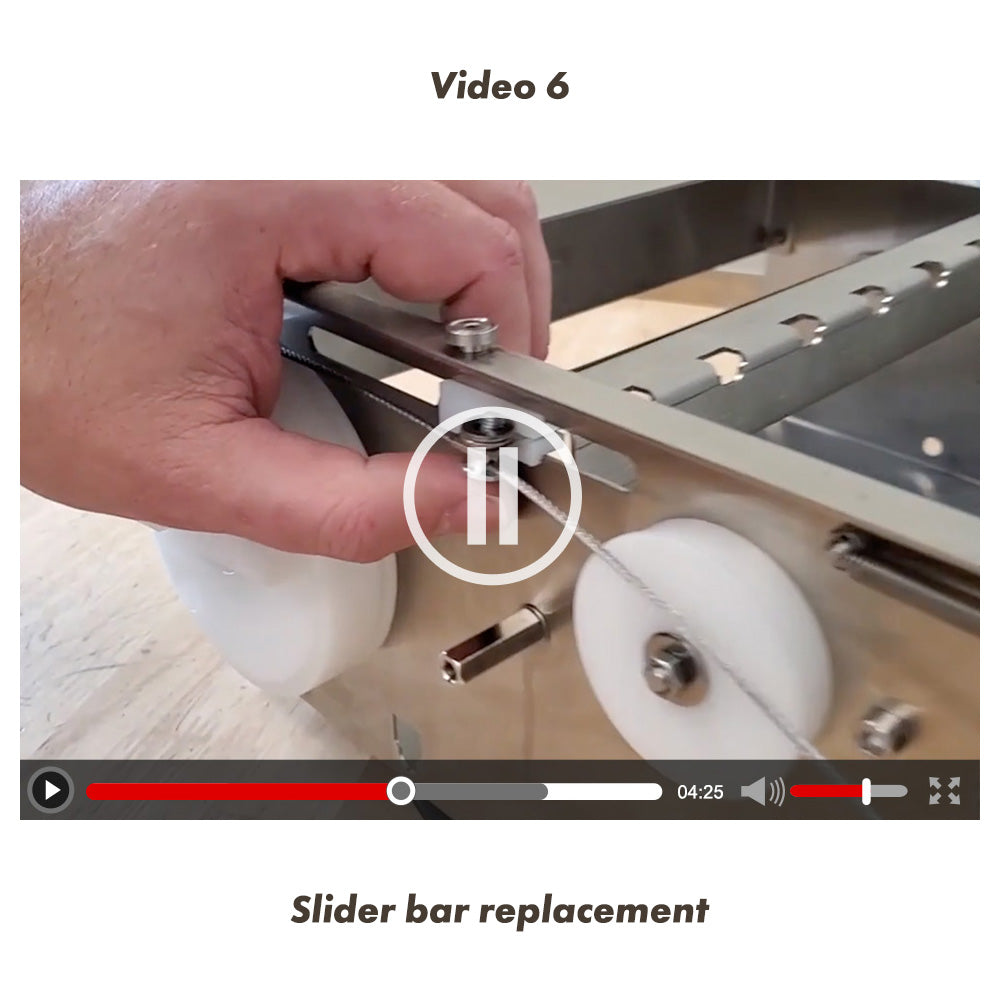

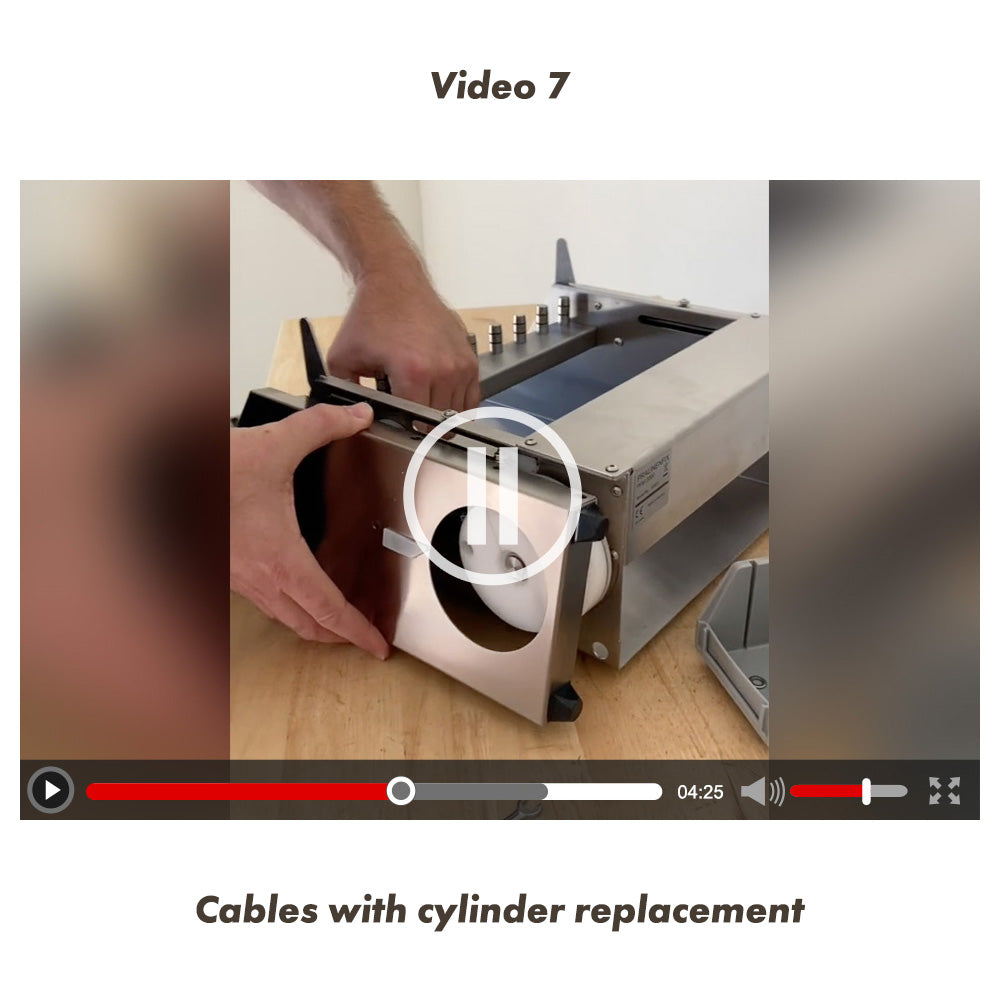

Truffly Made offers regularly-scheduled maintenance, routine checks, and emergency repairs for our machines. We also have Video Tutorials available to guide you through upkeep of our Universal Depositor.

If I watch the tutorials, is it easy to maintain Truffly Made equipment on my own?

In most cases, yes. We have a variety of spare parts available for our depositors and demolders.

Why is there inconsistent deposits across nozzles?

Inconsistent deposits are due to worn O-rings, worn Valve Stoppers, loose cables with cylinder, or mixture that is too thick or too liquid. It can also be due to improper temperatures, either too hot or too cold.

What temperatures should I set my depositor to?

Set temperatures vary depending on the product deposited. See the chart below:

Tempered White / Milk Chocolate: 85F / 29C

Tempered Dark Chocolate: 89F / 31C

Ganache / Fondant: 125F / 51C

Gelatin Gummy: 180F - 205F / 82C - 96C

Pectin Gummy: 205F - 220F / 96C - 104C

Taffy / Fudge: 220F - 235F / 104C - 112C

Caramel: 230F - 250F / 110C - 121C

Hard Candy: 266F - 285F / 130C - 140C

Please note that these temperatures are suggestive, and you might need to adjust accordingly with your recipe depending on the type and ratios of ingredients used.

Also, temperature of container can be set at a slightly higher point in order to keep the product warmer. Nozzles temperature can be set higher to reduce tails from higher viscosity products.

Make sure to pre-heat the depositor for a minimum of 45 minutes.

Why are pistons popping out of the slider bar during operation?

Pistons popping out of position is often due to viscosity of the mixture being too high, temperatures set being too low, or if cable and cylinder is loose or unevenly tightened. For machines more than 3 years old, the slider bar may be worn out and need to be replaced.

Why more product is being deposited on one side of the depositor?

If your mixture deposits are heavier on one side of the depositor compared to the other, please check the cables with cylinder located inside the base of the machine. Cables might be loose or unevenly tightened. Also, the slider bar might be angled and require recalibration.

Why isn't my product unmolding efficiently with the demolder?

Unmolding efficiency varies depending on product.

For gelatin gummies, we suggest preparing the molds with a releasing agent such as MCT oil, mineral oil, or similar before depositing the mixture. Also, placing your filled molds with set product in a fridge or freezer for a short amount of time (under 1 hour) can help solidify the product to facilitate unmolding with a demolder.

Unmolding efficiency also varies depending on your ingredients and process. Make sure to work in a controlled environment with temperatures below 72F / 22C and below 50% humidity. Product must be properly set in the molds before unmolding.

Avoid leaving any product in the mold for more than 24 hours before unmolding.

Why are there air bubbles in my deposited mixture?

If air bubbles are seen in the deposited product, it if often due to worn O-rings; specifically the O-rings at the bottom of the hopper threads or the piston inlet O-rings. Always replace all O-rings in a series to maintain consistency.

Another reason why you would see air bubbles is if the temperature of the nozzles is too high, which boils the mixture within the piston chamber. This is often paired with depositing discrepancies across nozzles.

Why do some nozzles seem to be depositing at as lower rate?

If some nozzles are depositing at a slower rate, it is due to the ball bearing at the bottom of the hopper that isn't flowing properly. This is due to lack of lubrication or improper priming. To get the ball bearing running properly, use a long tool such as thermometer probe to poke the ball from within the hopper.

Why are the O-rings for piston cylinders breaking or chipping?

O-rings for pistons cylinders should be replaced every 2-3 months; however, replacement frequency varies depending on viscosity and temperature.

If O-rings are breaking or chipping quickly, it is often due to excessively high product viscosity or lack of lubrication before reassembling the pistons. Always apply grease or oil while reassembling the pistons. MCT oil, mineral oil, or our special lubricating oil is recommended.

Can I test my machine with water?

Water does not have any viscosity; therefore, it will not go through the ball bearings and pistons. Water can be used at the end of production to flush the pistons from any remaining mixture, but once flushed out, the nozzles will stop depositing.

To test the machine, you can use plain corn syrup slightly warmed up with the temperature set to 120F / 50C.

How often should I service my depositor?

Recommended Preventive Maintenance

1. Replace 2 small O-rings around piston’s cylinder every 2-3 months.

2. Replace all other O-rings on the depositor

once to twice per year.

3. Replace Valve Stoppers (T-shapped rubber component) every 2-3 months.

4. Verify tension of metallic cables

with cylinder inside

depositor’s base once a month and

tighten if necessary. Replace cables once to twice per year.

We also offer depositors services for full refurbishing. This is recommended for machines that are 3 years old or older. Contact us for more information.